6 Steps to Choose the Best Plastic Parts Manufacturer in India for Electronic Parts

- Nov 13, 2024

- 5 min read

Updated: Feb 12, 2025

Are you aware that the choice of a plastic parts manufacturer can make or break the success of your electronics products? The quality of plastic components directly influences the performance, safety, and durability of electronic devices. For OEMs, and distributors in the electronics industry, it’s essential that these parts are crafted with precision and adhere to industry standards to maintain product quality and customer satisfaction.

In this blog, we’ll guide you through the process of selecting the best plastic parts manufacturer in India, focusing on key factors like material selection, manufacturer capabilities, and compliance with electronics-specific requirements. By the end, you'll be equipped with the knowledge to make an informed decision, and we’ll introduce you to Vidhata Plastics, a leading choice in India for manufacturing high-quality plastic parts for electronics.

Steps for Selecting the Plastic Parts Manufacturer in India

Step 1- Define Your Specific Requirements

Before diving into the search for a plastic parts manufacturer in India, it's important to clearly define your specific needs. This step ensures you find a manufacturer who can meet your expectations and provide parts that are functional, safe, and reliable for your electronics.

Material Selection

When manufacturing plastic parts for electronics, it’s essential to choose the right plastic material. Electronic parts often need to possess specific properties such as electrical insulation, heat resistance, and durability. Some of the common plastic materials used for electronic parts include:

ABS: Known for its toughness and good electrical insulation properties.

Polycarbonate: Highly durable and heat-resistant, ideal for enclosures.

Nylon: Strong, flexible, and resistant to wear, suitable for moving parts.

PEEK: Offers excellent mechanical strength and chemical resistance, often used in high-end electronics.

Each of these materials has different strengths, and the choice will depend on the exact function of the part and the environment it will be used in.

Part Complexity and Design

Consider the complexity of the parts you need. Are there intricate features, delicate components, or tight tolerances? A high-quality plastic parts manufacturer in India should be capable of producing complex designs with precision. They should also be able to work with CAD files and offer suggestions for optimizing designs for manufacturing.

Certifications and Industry Standards

Many electronic parts need to comply with specific industry standards. Depending on the end-use, you may need parts that meet RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), or REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. Ensure the manufacturer is familiar with these certifications and is capable of producing parts that meet these safety standards.

Step 2- Research Potential Manufacturers

Once your requirements are clear, the next step is to research potential plastic parts manufacturers in India. There are several ways to find reliable manufacturers:

Online Directories and Marketplaces

Platforms like IndiaMART, Alibaba, and Global Sources list hundreds of Indian manufacturers that specialize in electronics parts. These platforms allow you to filter manufacturers based on location, capabilities, and customer reviews.

Industry Networks and Associations

Associations such as the Plastics Export Promotion Council of India (PEPC) can provide recommendations for trusted manufacturers. These associations often have a list of certified manufacturers who meet industry standards.

Trade Shows and Exhibitions

Attending events like Electronica India or the India International Plastics Exhibition gives you a chance to meet manufacturers in person. This is an excellent opportunity to discuss your needs, see samples of their work, and get a feel for their manufacturing capabilities.

Step 3- Evaluate Manufacturer Capabilities

Not all manufacturers are created equal, and it’s important to evaluate the capabilities of each potential plastic parts manufacturer in India to ensure they can meet your specific needs.

Manufacturing Facilities and Equipment

Look for manufacturers with modern, well-equipped facilities. Advanced machinery, such as CNC and injection molding machines, ensures that the manufacturer can handle high-precision parts. If possible, a visit to the manufacturer’s facility is a great way to assess their production capabilities.

Experience and Expertise

Experience matters, especially when producing parts for electronics. Manufacturers with a proven track record of working with electronics companies are more likely to understand the specific challenges and requirements of these parts. Ask about their experience producing similar components, such as enclosures, connectors, or buttons.

Quality Control and Testing

Quality control is critical when producing parts for electronics, as even minor defects can cause serious problems. Ensure the manufacturer has stringent quality control measures in place, such as ISO certifications and in-house testing capabilities. Inquire about their quality assurance processes and how they handle defective parts.

Design and Engineering Support

Some manufacturers offer additional services, such as design assistance, prototyping, or tooling support. These services can be invaluable, especially if you need help optimizing your part designs for manufacturing or if you require rapid prototyping to test parts before full-scale production.

Step 4 - Request and Compare Quotations

After identifying a few potential manufacturers, request detailed quotations. Make sure to provide clear specifications, including drawings, dimensions, material requirements, and any special instructions. When comparing quotes, consider not only the price but also the following factors:

Minimum Order Quantities (MOQs): Does the manufacturer require large MOQs, or can they accommodate smaller production runs?

Lead Times: Can the manufacturer meet your deadlines for production and delivery?

Payment Terms: What are the payment terms, and are there any discounts for bulk orders?

Step 5- Conduct Due Diligence

Before making your final decision, it’s crucial to conduct thorough due diligence on each manufacturer.

Verify Credentials and Certifications

Check the manufacturer’s business license and certifications. For example, if you need parts that comply with RoHS or UL standards, make sure the manufacturer has the necessary certifications.

Customer Reviews and Testimonials

Look for online reviews or ask the manufacturer for testimonials from past clients. Reviews from other companies in the electronics industry can give you a better sense of the manufacturer’s reliability and quality.

Factory Visits

If possible, visit the manufacturer’s facility to get a firsthand look at their operations. This is an excellent way to assess their production capacity, cleanliness, and overall professionalism.

Step 6- Focus on Electronics-Specific Requirements

There are several key factors that are unique to this industry when choosing a plastic parts manufacturer in India for electronics.

Electrical Properties

Ensure the manufacturer understands the importance of maintaining electrical insulation, conductivity, and dielectric strength for parts like enclosures and connectors.

Thermal Management

For parts that need to dissipate heat, such as heat sinks, verify that the manufacturer has experience designing components that meet specific thermal requirements.

Environmental Compliance

If your electronics parts need to comply with environmental regulations like RoHS or REACH, ensure the manufacturer is familiar with these standards and can produce compliant components.

Vidhata Plastics: Your Trusted Partner for Electronics Parts

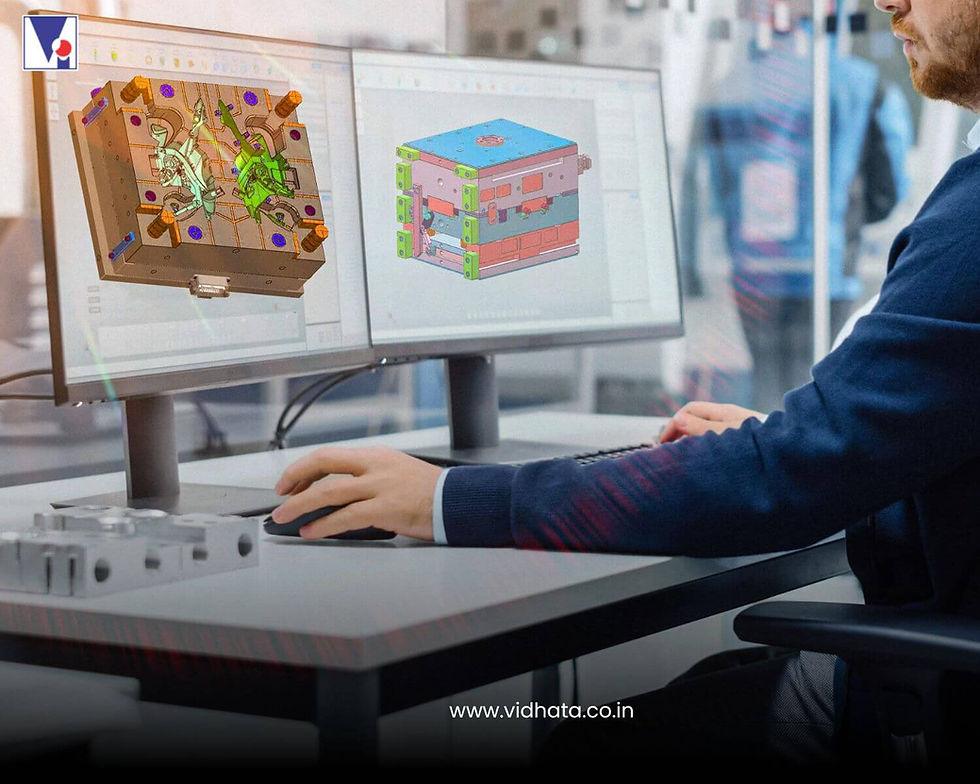

When it comes to finding the best plastic parts manufacturer in India, Vidhata Plastics stands out as a leader in the industry. With years of experience in plastic injection molding, Vidhata Plastics is well-equipped to manufacture high-quality plastic parts for the electronics industry. They specialize in producing complex components like enclosures, connectors, and buttons, ensuring precision, durability, and compliance with industry standards.

Vidhata Plastics offers:

Advanced manufacturing capabilities with state-of-the-art machinery.

Expert design and engineering support to help optimize your part designs.

Stringent quality control processes to ensure consistent, high-quality parts.

Whether you need small or large production runs, Vidhata Plastics can meet your requirements and help you bring your electronics products to market efficiently and cost-effectively.

Conclusion: Choosing the right plastic parts manufacturer in India is a crucial decision for electronics OEMs and distributors. By following the steps outlined in this guide—defining your needs, researching potential manufacturers, and conducting due diligence—you can ensure that your electronics parts are produced to the highest standards.

For those looking for a reliable partner, Vidhata Plastics is the best choice for high-quality plastic parts manufacturing in India. Contact Vidhata Plastics today to discuss your project and see how they can meet your specific needs.

Visit Our Website: https://www.vidhata.co.in/

Contact Us: https://www.vidhata.co.in/contact

Email Id: info@vidhata.co.in

WhatsApp No. : +919550665666

Comments